Supply Chain

SUPPLY CHAIN PROCESSES MANAGED

• Preparation of model & molds,

• Production and processing of sand and lost-wax castings

• Free or close-die forgings, machined

• Hot-rolled rings, rough or finish machined

• Custom metal cutting

• Custom light, medium and heavy welding fabrication

• Special alloy overlays

• Additive manufacturing (DMLS - EBM - SLS)

• Thermal treatments

• Surface Treatments and Paintings

• NDT Inspections

• Chemical analysis

• Product mechanical testing

• Custom machine roughing or finishing

• CMM dimensional measurement certification, on request

• Mounting

• Functional pressure tests

• Recovery and regeneration of hydro machines

• Logistics and emergency services

• Reverse-engineering at customer’s request

WHAT WE DO IN CONCRETE TERMS

We coordinate several stages of the production process: from customer drawings to manufacturing of finished components and, if required, to their fitting.

We simplify your purchasing process by giving you complete all-round guarantees with regard to execution times and product quality, providing.

• Mechanical components finished to drawing

• Complete turbine distributors

• Turbine injectors

• Finished and balanced, new and remanufactured turbine runners

• Finished Kaplan vanes

• Components for centrifugal machines

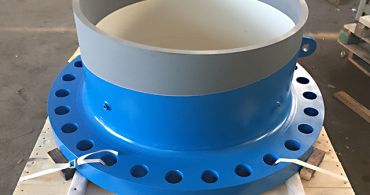

• Finished pump housings and valve bodies

• Bearings, bushings, seals

• Finished and NDT-tested servomotors

• Guide and thrust shoes

• Decanters with leak test

• Finished and balanced pump runners

• Finished shafts and rotors

• Assembled reducers and multipliers

• Bypass Valves

• Impellers for turbocompressors

• Mountings

• NDT